Quality Control System

It is very easy to produce quality product Once, But very tough to deliver same consistently…

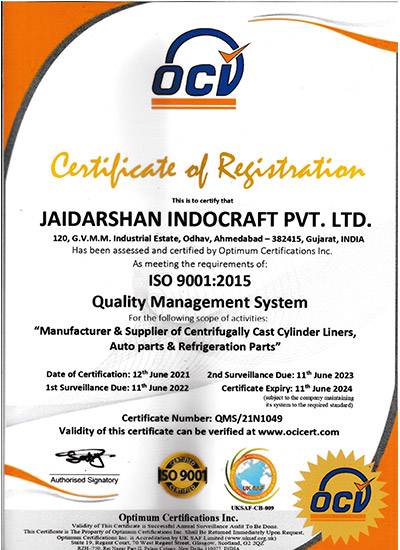

A dedicated team of qualified Engineers maintains the most stringent quality control standards and ensures that nothing short of perfection reaches out. We are following a system of inspecting the product in process after all the stages of manufacturing cycle. Our product undergoes stringent quality control tests right from the raw material stage to the finished product. Documentation and Evaluation of all important manufacturing steps – from material composition to final inspection before dispatch – ensures that we consistently produce top quality products meeting international standards. Specially designed Jigs and fixtures are used therefore.

Being a quality oriented organization we have standard criteria set to evaluate each and every raw material and Work in process. We put every product against same criteria which helps us to produce zero defect quality products.

Special alloys of specified grade are purchased to meet input standards. Again the molten metal is checked with in-house metal analyzer purchased from World renowned Suyash Enterprise, Pune. Once liner cast they are taken to machining department where specially made jigs and fixtures act as Go, No go gauge and perform machining as well as decide whether the product is within permissible limit or not.

Design and development of new products are also routed through the APAQ Process Quality, integrated into the manufacturing process through:

- Process monitoring and operating instructions

- Control plans and checklists

- Set-up approval

- Process capability evaluation

Call us now – +91 93779 67468 or more information enquire us at info@engineliner.com